- +91 9923275454 +91 9823537171

- swastikindustries_2008@yahoo.com

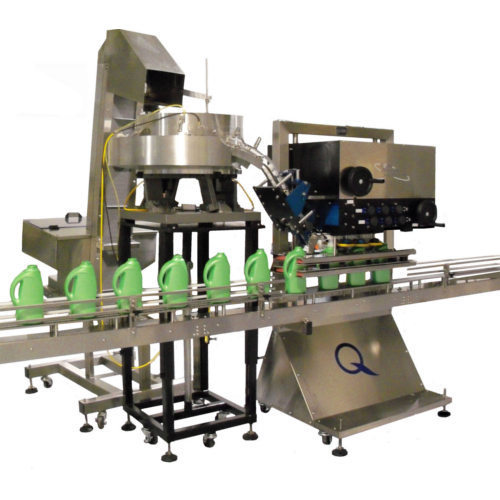

Oil Filling & Packaging Machines

We Swastik Industries are leading manufacturers,suppliers,exporters of Oil Filling and Packaging Machines in Pune, Maharashtra.

Oil filling and packing machines are a versatile and efficient way to package a wide variety of oils. By automating the packaging process, oil filling and packing machines can help businesses to increase productivity, improve accuracy, enhance product protection, reduce labor costs, and branding opportunities.

If you are looking for an oil filling and packing machine, be sure to do your research to choose the right machine for your needs

| Weight | : | 150 Kg. Approx. |

| Dimension | : | 700 x 500 x 1000 mm. |

| Power | : | 0.5 H.P. Single / Three Phase |

| Filling Range | : | 5 gm to 20 gm |

| Filling Material | : | any thick paste as lime, grease mehndi, shrikhand |

| Pouch Length | : | 1" to 5" |

| Speed | : | 3000 Pouch / hr. |

What is an oil filling and packing machine?

An oil filling and packing machine is a piece of machinery that is used to automatically fill and seal containers with oil. Oil filling and packing machines are typically used in the food, beverage, industrial, and other industries to package a wide variety of oils, such as edible oil, cooking oil, lubricant oil, and more.

How does an oil filling and packing machine work?

- • The basic steps involved in the oil filling and packing process are:

- • The machine loads the containers onto a conveyor belt.

- • The machine fills the containers with oil.

- • The machine seals the containers.

- • The machine ejects the sealed containers from the machine.

The specific steps involved in each of these steps can vary depending on the type of oil filling and packing machine. However, all oil filling and packing machines work on the same basic principle.

Types of oil filling and packing machines

Volumetric oil filling and packing machines: These machines measure the amount of oil to be filled by volume. Volumetric oil filling and packing machines are typically used for filling oils that have a consistent viscosity, such as edible oil and cooking oil.Weight-based oil filling and packing machines: These machines measure the amount of oil to be filled by weight. Weight-based oil filling and packing machines are typically used for filling oils that have a variable viscosity, such as lubricant oil.

Features of oil filling and packing machines

Oil filling and packing machines can have a variety of features, including:

- Different filling speeds: Oil filling and packing machines can be configured to fill containers at different speeds. This allows businesses to choose the machine that best meets their production needs.

- Different filling methods: Oil filling and packing machines can use different filling methods, such as peristaltic pumping, piston pumping, and diaphragm pumping. The filling method that is best suited for a particular oil will depend on the oil's viscosity and other factors.

- Different options for container loading: Oil filling and packing machines can be configured to load containers in a variety of ways. This allows businesses to choose the loading method that best meets their production needs.

- Different options for container sealing: Oil filling and packing machines can be configured to seal containers in a variety of ways. This allows businesses to choose the sealing method that best meets their production needs.

- Different options for container labeling: Oil filling and packing machines can be configured to label containers in a variety of ways. This allows businesses to brand their products and comply with labeling regulations.

Benefits of using oil filling and packing machines

Increased productivity: Oil filling and packing machines can help businesses to increase productivity by automating the packaging process.

- Improved accuracy: Oil filling and packing machines can help businesses to improve accuracy by ensuring that containers are filled and sealed consistently.

- Enhanced product protection: Oil filling and packing machines can help to protect products from contamination and damage by providing a secure and tamper-evident packaging solution.

- Reduced labor costs: Oil filling and packing machines can help businesses to reduce labor costs by eliminating the need for manual filling and packing.

- ding opportunities: Oil filling and packing machines can be configured to label containers in a variety of ways. This allows businesses to brand their products and comply with labeling regulations.